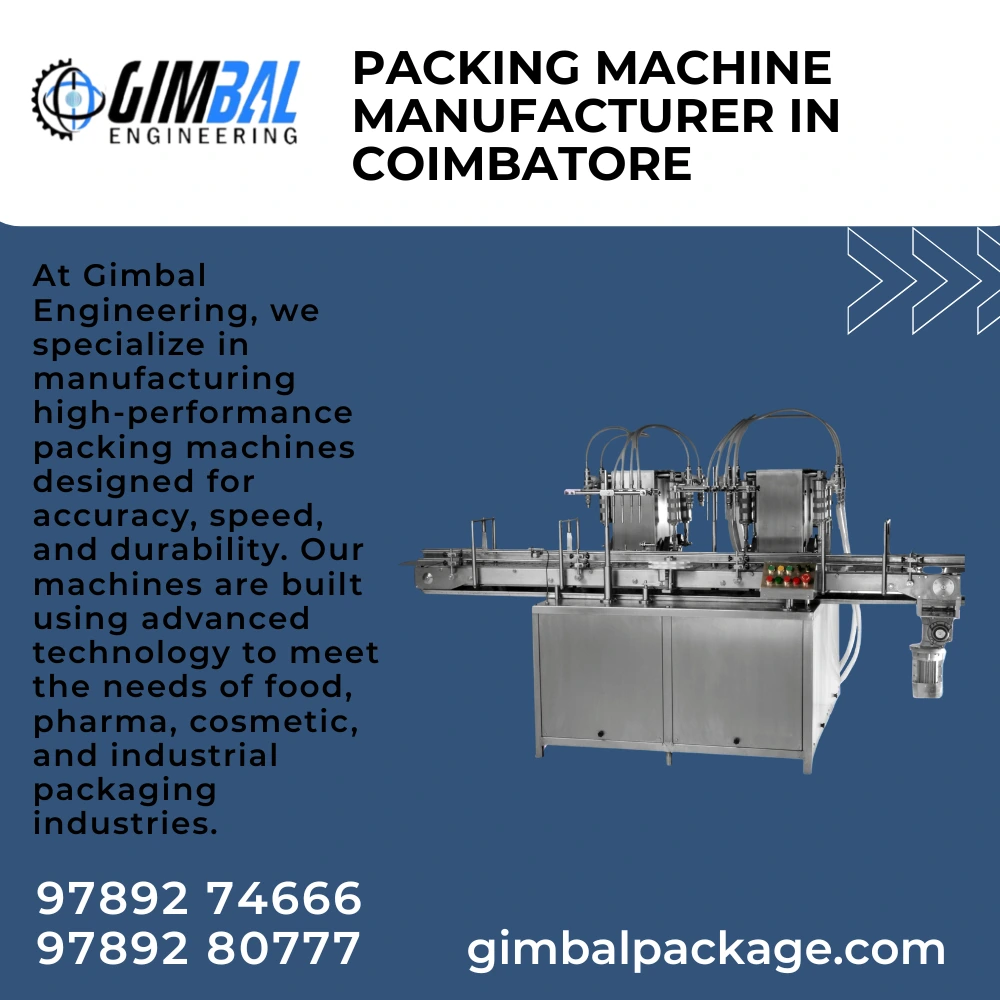

Packing Machine Manufacturer in coimbatore

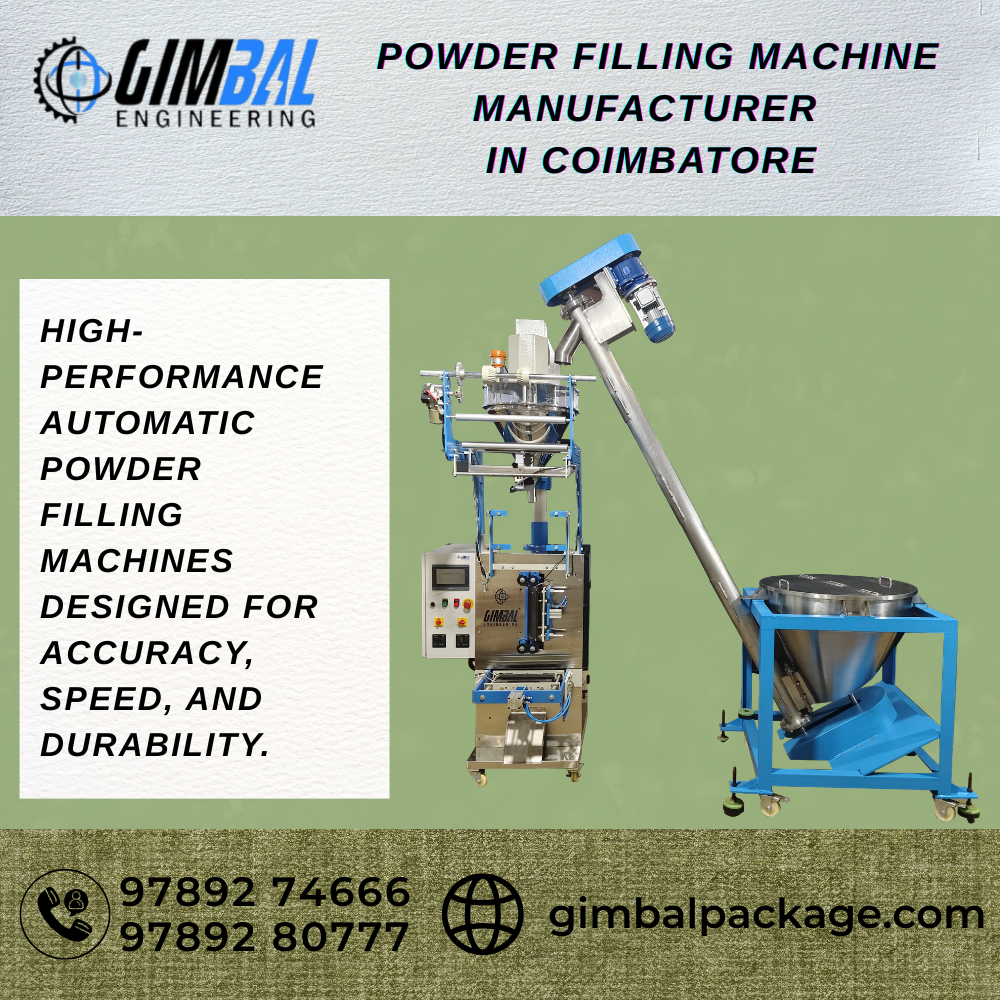

Packing Machine Manufacturer in coimbatore plays a key role in modern production lines by reducing manual work and increasing packing speed. Gimbal Engineering develops machines that automate filling, sealing, and wrapping processes, ensuring uniform results with every batch. These machines are ideal for food processing units, pharmaceuticals, chemical industries, and consumer goods manufacturers. By integrating smart mechanical design with durable components, the machines provide consistent performance even during continuous operation. This helps manufacturers meet market demand without compromising on quality. Precision Engineering and Robust Construction Gimbal Engineering emphasizes precision in every part of its packing machines. High-quality materials and carefully engineered parts ensure long-lasting performance and minimal breakdowns. The machines are built with strong frames and stable mechanisms that allow smooth functioning at higher production capacities. The accurate control systems help in maintaining correct weight, volume, and seal quality. This prevents product loss and ensures that each package meets required standards, enhancing the overall reliability of the packaging process. Applications Across Multiple Industries Packing machines manufactured by Gimbal Engineering are suitable for various industrial sectors. They are widely used in food packaging for items such as powders, granules, and liquids. In pharmaceutical and chemical industries, the machines provide secure and contamination-free packaging. Their flexible design allows them to handle different pouch sizes and materials, making them suitable for both small-scale and large-scale production units. This adaptability makes the machines a valuable investment for growing businesses. Hygiene and Safety in Packaging Packaging requires strict hygiene standards, especially in food and pharmaceutical industries. Gimbal Engineering designs its machines using materials that are easy to clean and safe for product contact. Smooth surface finishes and minimal joints help reduce residue buildup and simplify maintenance. Safety features are also incorporated to protect operators during machine operation. Emergency stop systems and guarded moving parts ensure a secure working environment, reducing the risk of accidents on the production floor. User-Friendly Operation and Maintenance Ease of use is a major factor in the success of any packaging machine. Gimbal Engineering focuses on user-friendly designs that allow operators to control machine functions with minimal training. Simple control panels and accessible components make daily operation smooth and efficient. Maintenance is also simplified through durable components and modular construction. Routine servicing and cleaning can be done quickly, reducing downtime and improving overall production efficiency. Supporting Business Growth Choosing the right Packing Machine Manufacturer can directly influence production capacity and profitability. Gimbal Engineering provides solutions that help businesses scale their operations while maintaining packaging accuracy and speed. The machines are designed to meet both current and future production needs. With customization options available, customers can select machines tailored to their specific product types and packaging requirements. This ensures optimal performance and better return on investment. Conclusion For industries seeking dependable packaging solutions, Gimbal Engineering offers high-quality machines built for efficiency, durability, and hygiene. Its commitment to innovation and customer satisfaction makes it a reliable partner for modern manufacturing needs. If you are searching for a trusted Packing Machine Manufacturer in Coimbatore, Gimbal Engineering delivers advanced packaging equipment that supports productivity, quality, and long-term operational success. Contact Us OR Visit Our Factory Directly.

Packing Machine Manufacturer in coimbatore Read More »