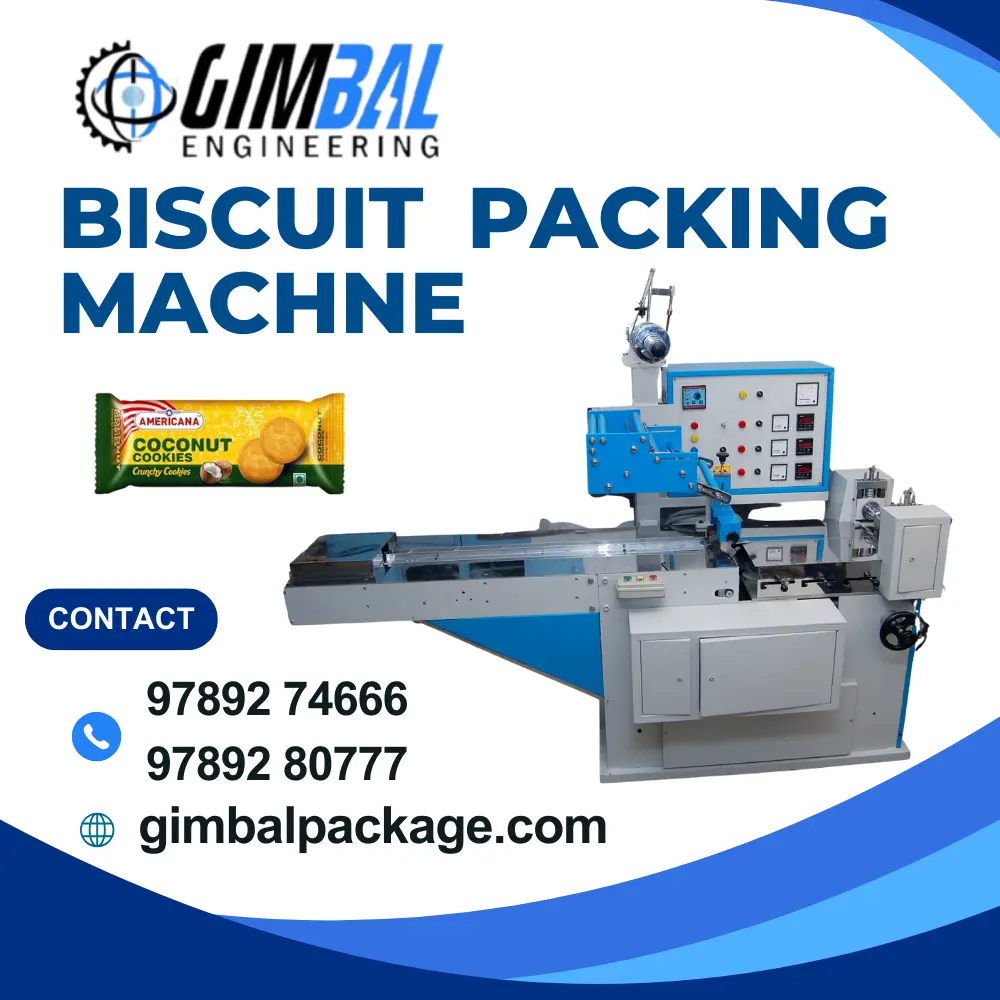

Packing Machines Manufacturer in Coimbatore – Gimbal Engineering

Packing Machines Manufacturer in Coimbatore – Gimbal Engineering In today’s fast-paced market, efficient packaging solutions have become essential for every manufacturing and commercial business. From food products to industrial goods, reliable packaging not only protects the product but also enhances brand value, increases shelf life, and enables smooth handling. As a leading Packing machines manufacturer in Coimbatore, Gimbal Engineering stands at the forefront of delivering technology-driven, durable, and high-performance packaging equipment trusted by industries across Tamil Nadu and India. With a strong commitment to engineering excellence and customer satisfaction, Gimbal Engineering designs and manufactures a wide range of packing machines suitable for small-scale units, medium industries, and large manufacturing facilities. Their machines are known for precision, speed, low maintenance, and long-term reliability. Why Gimbal Engineering is the Best Packing Machines Manufacturer in Coimbatore 1. Advanced Technology & Superior Engineering Packing machines manufacturer in Coimbatore by Gimbal Engineering integrates advanced automation, precision components, and innovative design in every packing machine. Their equipment ensures accurate filling, sealing, and packaging with minimal wastage and maximum productivity. Whether you need a machine for powder, granules, liquid, or solid products, they offer solutions tailored to your production needs. 2. Wide Range of Packing Machines As a trusted packing machine manufacturer, Gimbal Engineering provides machines for various industries, including food processing, pharmaceuticals, chemical manufacturing, agriculture, cosmetics, and household products. Popular models include: Automatic pouch packing machines Vertical form fill seal (VFFS) machines Liquid filling and sealing machines Powder packing machines Granule packing machines Semi-automatic and fully automatic packing machines Weighing and sealing machines Each machine is built to handle continuous operations while maintaining superior accuracy and stability. 3. High-Speed, High-Accuracy Performance Packing machines manufacturer in Coimbatore – Gimbal Engineering understands the production challenges faced by modern industries. Their packing machines are engineered for high-speed operations without compromising on precision. Whether it’s weight accuracy, sealing quality, or product consistency, their machines perform flawlessly even under heavy-duty cycles. 4. Durable Construction with Quality Materials All machines are made using industrial-grade stainless steel and corrosion-resistant materials. This ensures long-lasting performance, better hygiene (especially for food packaging), and easy cleaning. Every component is rigorously tested to ensure durability and smooth functioning. 5. Customised Packaging Solutions Every industry has unique packaging requirements. Gimbal Engineering offers customised machine configurations based on product type, packaging size, production volume, and budget. Their team of engineers works closely with clients to deliver efficient and cost-effective packaging solutions. Key Features of Gimbal Engineering Packing Machine Manufacturer in Coimbatore Consistent filling accuracy Heavy-duty construction Touchscreen controls and user-friendly interface Energy-efficient and low-power consumption High-quality sealing for better protection Low operational noise Minimal maintenance and easy servicing Safety features for operator protection Compact design suitable for all types of production units Industries Benefiting from Gimbal Engineering Machines Packing machines manufacturer in Coimbatore – Gimbal Engineering are widely used across: Food and beverage industry Snacks and bakery items Spices and masala manufacturers Rice, pulses, and grains packaging Pharmaceutical and healthcare Cosmetics and personal care products Fertilizers and chemical industries Detergent and cleaning products Oil, ghee, and liquid manufacturers Their machines ensure smooth workflow, reduced labour, and higher output, making them the preferred choice for both startups and established companies. Why Packaging Machines Are Important for Modern Businesses In today’s competitive market, businesses cannot afford delays or inconsistencies. High-quality packaging machines offer several advantages: Increased production speed Controlled packaging costs Enhanced product safety and shelf life Improved branding with neatly sealed packs Reduced human error and labour dependency Better hygiene and quality assurance Gimbal Engineering helps businesses achieve all these benefits with its advanced and reliable machinery. Gimbal Engineering – Committed to Excellence As a reputed packing machines manufacturer in Coimbatore, Gimbal Engineering continues to deliver machines that combine innovation, performance, and durability. Their focus on customer satisfaction, prompt after-sales support, affordable pricing, and industry-grade quality sets them apart from competitors. Contact Gimbal Engineering or Visit our location directly.

Packing Machines Manufacturer in Coimbatore – Gimbal Engineering Read More »